Improve key customer metrics like NPS, customer effort, and CSAT

Proactive and Preventive:

Data Generation Is Not The Problem

Using scalable advanced analytics in predictive maintenance.

The ability to manage a variety of asset types and avoid unplanned downtime is no trivial task. An entire operation can come to a halt if just one critical process, asset, or machine fails. But too often organizations are forced to rely on outdated, incomplete, or inaccurate data to make decisions resulting in inefficient operations.

The #1 driver for investments in predictive maintenance among service leaders is the need to have a faster response to product quality and service issues.

As more products and equipment are connected providing a wealth of data points, data availability is no longer the primary problem impacting organizations’ ability to improve maintenance, service, and support.

Siloed processes and data, lack of a scalable, high-performance data analysis platform, and analytic methods focused only on past performance hinder the ability to shift from reactive maintenance to more proactive, predictive, and prescriptive models.

Source: IDC Manufacturing Insights Product and Service Innovation Survey, 2021

Shortcomings of Break/Fix and Reactive Service Models

Unplanned downtime is more than just a nuisance to facilities, plant, and field service operators

of manufacturers still characterize their service, operational, and maintenance approach as break/fix and reactive.

of manufacturers find it very difficult to address challenges resulting from a lack of process automation, inefficiencies in workflow (e.g., manual, duplicative, siloed work), and delays in transforming data from information to knowledge.

Only 14% of manufacturers rate themselves as excellent at surfacing actionable information to all users in the flow of work.

Sources: IDC’s Future of Intelligence Survey, 2021 and IDC Manufacturing Insights Product and Service Innovation Survey, 2021

The Promise of Predictive Maintenance

Turn smarter equipment, assets, and products into better outcomes

The Right Outcomes Need Relevant and Timely Insights

Q: What are the top five drivers for your organization’s service life-cycle management efforts?

(%of responses)

Faster Response to product quality & service issues

Establish more capabilities around remote service, collaboration, and resolution

Improve key customer metrics like NPS, customer effort, and CSAT

Use information from actual product and asset performance

Improve collaboration between cross-functional teams

Capture and make accessible service knowledge and best practices

Source: IDC Manufacturing Insights Product and Service Innovation Survey, 2021

The Right Outcomes Need Relevant and Timely Insights

Q. What percentage of products your organization currently manufacturers are considered “connected” (i.e., have a unique IP address and software within them to enable service and product performance information to be communicated over a wireless network)? What will that be in three years?

44%

Today

60%

3 years

from now

Improve service and maintenance through data-driven, near-real-time insights

31%

of manufacturers

are seeing a shift to:

60%

of manufacturers

are seeing a shift to:

The future of maintenance is:

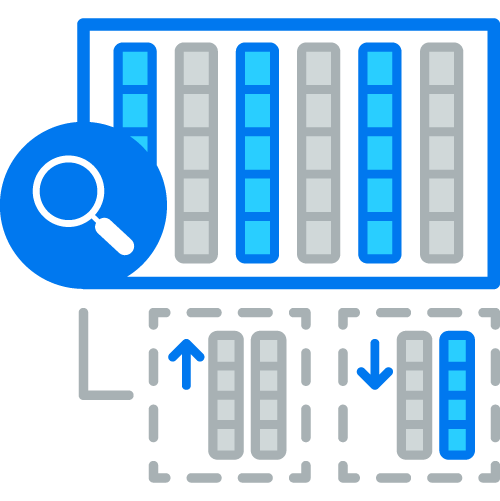

A Modern, Scalable, Data Analytics Platform

Support for data exploration and decision automation

Decision Making, Data, and Analytics Usage Patterns

Data exploration

and investigation

Key driver identification

Guided root-cause analysis

Data exploration and investigation is about helping users understand and explain what happened and why it happened.

Decision

Automation

Conditional decision automation

Algorithmic decision automation

Decision automation is about automating tactical decision making in the flow of operations.

Consider the following predictive maintenance decision variables:

Requirements of a modern data analytics platform for predictive maintenance

Source: IDC, 2022

What steps should organizations take to solve the problem or seize the opportunity?

Insights at Scale

Complexity of Maintenance Operations Doesn’t Require a Complex Response

Develop a long-term data and analytics strategy that considers various decision-making patterns and related data and analytics IT requirements – both for streaming and batch data processing and analysis at scale.

Assess data quality and availability guaranteeing data-driven decisions can be made.

Consider IT partners that provide a modern data, analytics and AI platform that is extensible and leverages a broad partner ecosystem as no single vendor can do it all.

Don’t expect a single technology to address all requirements. SQL-based, columnar, MPP analytic databases have a role, so do data lakes and streaming data processing software, and a range of upstream and downstream data integration and data analysis and visualization tools.

Select appropriate data and analytics technology that is not just about finding solutions with the most compute power or storage capacity (and flexibility); also consider security, support from solution provider, and overall total cost of ownership.

Source: IDC, 2022

View PDF of infographic created by IDC Insights.

How can predictive maintenance help you see problems long before they happen?

Learn how a modern, scalable data analytics platform can remove the guesswork and unnecessary labor and expense of a traditional, scheduled maintenance approach.

Vertica is the analytical database with the best value for the highest performance on any data analytics, at any scale, anywhere.

Learn more about using Vertica as part of a modern, scalable, data analytics platform for predictive maintenance